- Yukha

- News and advice on hydroponics culture indoors and outdoors!

- 38 likes

- 35398 views

- 0 comments

The web translation of Yukha's original (Spanish, French, English) text may contain some errors and misunderstandings. We apologize for inconveniences caused.

There is no doubt that the best coconut substrate is used by horticultural professionals.

Indeed, a large part of the greenhouse production is now carried out on 100% coconut substrate.

The requirements of professionals are very precise and concern above all an excellent relationship between water retention and the presence of air.

Coconut substrates are composed of a mixture of spongy particles and of fiber.

- The more fiber the substrate contains, the lower its water retention. This will make irrigation management particularly complicated.

- The smaller the spongy particles, the greater the risk of settling the substrate.

The question you are asking yourself is: how to know if my coconut substrate is of good quality, the answer is simple: speak directly to a manufacturer or to the direct representative of a manufacturer and do not hesitate to ask technical questions to your supplier such as the following for which we also indicate the desirable values.

- What is the water retention of your coconut substrate in liters/kg?

- Desirable value: between 6.5 and 7 liters/kg

- What is the minimum particle size?

- Desirable value: 0.8 mm

- What is the % of short fibers?

- Desirable value: between 5 and 7%

- What is the rate of organic matter?

- Desirable value: minimum 98%

- What is the product date of manufacturing?

- Desirable value: maximum 18 months

A good substrate should ensure a good availability of water, oxygen, and nutrients.

- Water availability will depend on the substrate ability to retain and release it

- Air availability will depend on the granulometry and texture of the substrate

- Nutrient availability will depend on the substrate's ability to exchange

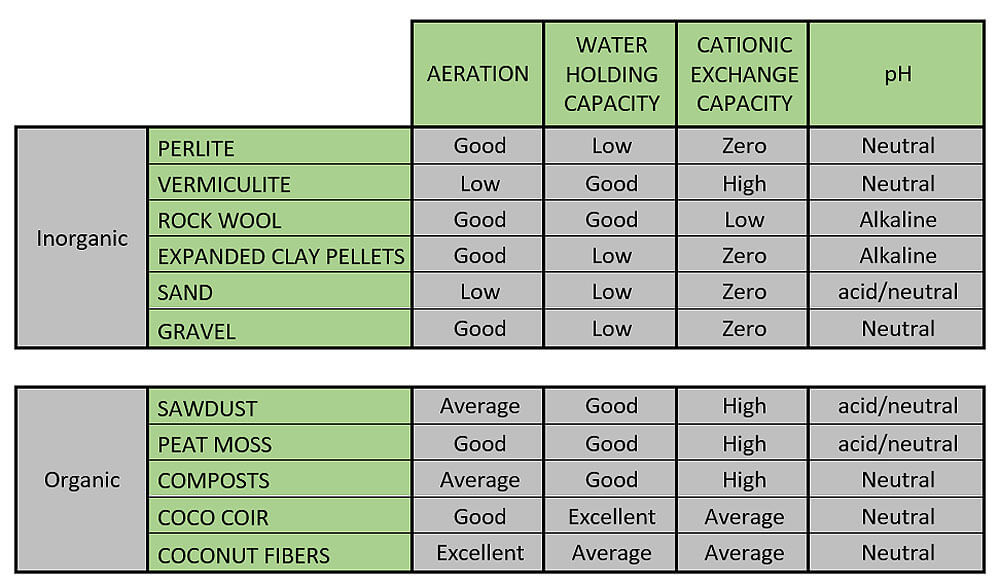

To help you select your substrate, we have prepared a comparative table that presents the main physical and chemical characteristics of each of them:

The main qualities of your substrate for better results:

- Protects plants from excessive pH variations

- has a high aeration rate (this rate should be maintained over time)

- Has a high level of Plant Available Water (PAW)

- Has an average cationic exchange capacity

- Is environmentally friendly

- Is biodegradable

Let us summarize the main qualities and defects of inorganic and organic substrates:

- Perlite

- Its qualities:

- Airy

- Light

- Reusable

- Good drainage capacity

- Its flaws

- Not environmentally friendly because it requires large amounts of energy to be manufactured.

- No buffer effect and extremely low water retention.

- Conclusion

- Perlite is mainly used in mixtures or in hydroponic systems

- It is advisable to use it as a mixture to improve very low-quality organic substrates.

- Its qualities:

- Vermiculite

- Its qualities

- Good PAW

- Low density

- High Cationic exchange capacity

- Its flaws

- Low ventilation

- Not environmentally friendly because it requires large amounts of energy to be manufactured.

- Low drainage capacity

- Conclusion

- Vermiculite is mainly used in mixtures or hydroponic systems (it is advisable to mix it with perlite on a 50/50 basis in the hydroponic systems)

- Just like perlite it is recommended rather in mixture to improve organic substrates of exceptionally low quality but pay attention to its high water retention and low aeration.

- Its qualities

- Rock wool

- Its qualities

- Good PAW

- Excellent aeration

- Good drainage capacity

- Its flaws

- Zero cationic exchange capacity

- Not environmentally friendly because it requires large amounts of energy to be manufactured.

- Highly polluting, cannot be recycled

- Conclusion

- Rock wool that is still used by horticultural professionals is gradually abandoned in favor of organic substrates and mainly those based on the mesocarp of the coconut.

- Rock wool is exclusively used in 100% hydroponic production systems

- Rock wool is not recyclable, and most recreational producers have abandoned it in favor of coconut.

- Its qualities

- Expanded clay pellets, sand, and gravel

- Their qualities

- Excellent aeration

- No risk of compaction 'except for sand)

- Excellent drainage capacity

- Their flaws

- Zero cationic exchange capacity

- No buffer effects

- PAW almost zero (except for sand)

- Important weight (except for clay pellets)

- Conclusion

- These 3 substrates are gradually abandoned in favor of organic substrates because their use is very restrictive and does not allow any mistakes.

- Clay pellets, which require a great deal of energy during their manufacturing, no longer correspond to the ideal of recreational producers aware of the pollution associated with the use of this substrate.

- Their qualities

- Sawdust

- Its qualities

- Organic substrate from renewable sources

- Good cationic exchange ability but watch out for pH

- Good PAW

- Its flaws

- Risks of plant asphyxiation

- Risk of water saturation

- High risk of nitrogen consumption resulting in yellowing of plants

- pH instability and difficulties in adjusting fertilization

- Conclusion

- This substrate is almost never used in recreational production because it is difficult to manage fertilization

- The most important point is that it is almost impossible to precisely know the actual composition of the sawdust. The substrate can be chemically very unstable.

- Its qualities

- Peat moss

- Despite their many qualities, we should no longer use this substrate, which is now rare. Its use goes against any awareness of environmental protection.

- Compost

- Its qualities

- Organic substrate from renewable sources

- Good cationic exchange ability but watch out for pH

- Good PAW

- Its flaws

- Risks of plant asphyxiation

- Risk of water saturation

- If the soil is not "ripe" there is a significant risk of high nitrogen consumption resulting in yellowing of the plants

- pH instability and difficulties in adjusting fertilization

- Conclusion

- This substrate is widely used in recreational production, but it is difficult to manage fertilization

- It’s always necessary to ensure that the substrate is well mineralized and well stabilized because if otherwise, then it can be chemically very unstable.

- Its qualities

- Coco coir and coco fiber

- These substrates will be the subject of a more detailed blog, but we can summarize the main characteristics as we did for other inorganic and organic substrates

- Their qualities

- Organic substrate from renewable sources

- Good ability to exchange cationic

- Excellent PAW (but not for pure fibber)

- Excellent aeration capacity

- Their flaws

- Uncertain sources of supply

- Risk of water saturation if the proportion of small particles is too high

- Very inadequate drainage if the proportion of small particles (<1mm)

- Difficulties in adjusting irrigations if the substrate is of insufficient quality

- Conclusion

- Coconut substrates are now the most widely used all over the world as they have demonstrated their absolute superiority

- The biggest problem is the quality of supply sources, that business has attracted many people and mainly traders who do not really care about maintaining quality.

- Nevertheless, coconut substrates still have a bright future ahead as they have demonstrated their great technical superiority and their perfect match with a certain awareness of environmental protection.

In a future blog, YUKHA will go into more detail about the use of coconut substrates in professional agriculture and will share in detail his passion for this product which, let us not forget, comes mainly from India....

Yukha!

![]()

Comments (0)